Arzatoarele pe peleti ecoHORNET inlocuiesc arzatoare pe gaze, motorina, ulei, pacura, GPL, CLU, etc. la echipamente noi sau folosite, facilitand accesul la o energie termica iefina si ecologica.

Rezultatele exceptionale obtinute cu ocazia omologarii noului arzator: randament peste 94%, emisii de CO sub 250mg/m³, COV sub 10mg/m³ si, in special, al emisiilor de particule de sub 7,4mg/Nm³ au creat conditiile tehnice necesare fabricarii arzatoarelor pe peleti tip injector si ne indreptatesc sa spunem “adio” injectoarelor si arzatoarelor pe gaze, motorina, lei, pacura, GPL, CLU, etc.

Energie verde si economii de minim 50% din factura de energie termica

Atat pentru industrie cat si pentru agricultura sau constructii, uz rezidential, arzatoarele ecoHORNET cu functionare pe peleti fabricati din biomasa, in locul celor pe combustibili osili, poluanti, reduc semnificativ cheltuielile cu energia precum si emisiile de CO si particule. Utilizarea energiei regenerabile in activitatea intreprinderii determina cresterea eficientei energetice a intregii companii, produsele realizate au cost de productie competitiv, iar compania isi imbunatateste imaginea corporativa prin respect pentru mediu.

Aplicatii

•centrale termce pe lemn sau combustibili fosili

•cuptoare

•convectoare, generatoare de aer cald

•cazane abur

•uscatoare de cereale

•schimbatoare de caldura

•cazane cu ulei diatermic

•producerea de energie electrica, la instalatii cu

turbine sau motoare Stirling

Avantaje

•singurele arzatoare ce colecteaza cenusa in exteriorul schimbatorului de caldura

•autocuratire

•sistem de accelerare a arderii la folosirea peletilor inferiori energetic

•96-99% randament

•acces la un combustibil ieftin, ecologic, rapid regenerabil.

•independenta utilizatorului fata de politicile de taxe si accize la combustibili fosili, de retele de transport si

distributie.

Dotare Standard

• arzator tip injector ecoHORNET

• sistem de alimentare cu snec

• automatizare Sigmatek GmBH, display touch color, control si comanda prin internet

•rezervor de peleti pentru AHP20-200

• termostat ambiental sau senzor temperatura agent termic, in functie de aplicatii

•set de protectie electrica cu UPS, stabilizator, invertor, redresor 2 acumulatori 50A

Arzator

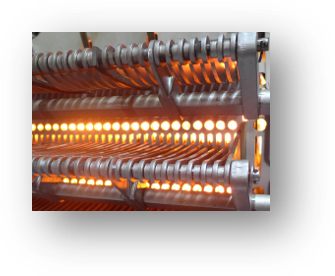

Arzatorului multisistem ecoHORNET patentat dezvolta temperaturi de ardere a peletilor de peste 1250°C, toata puterea calorica a combustibilului este valorificata, transformandu-se in energie termica. Randamentul arderii este aproape de 100%, arderea este completa, fara fum in gazele de ardere.

Arzatorul ecoHORNET este mobil, cu autocuratire si accelerarea arderii pentru cazul utilizarii unor peleti mai slabi energetic.

Arzatorul si camera de ardere sunt fabricate din inox special, rezistent la temperaturi peste 1300°C si la variatii de temperatura.

peste 1300°C si la variatii de temperatura.

Sistem de accelerarea a arderii si curatare gratar

Arderea fara fum si gudron in gazele evacuate permite functionarea cu tiraj fortat. Exhaustorul este montat la evacuarea de gaze de ardere.

Functionarea cu tiraj fortat asigura 100% controlul fluxului de oxigen necesar arderii, arderea este uniforma in toata masa de peleti aflati in arzator se realizeaza arderea completa, inclusiv a particulelor de fum.

Fiecare particula de pelete primeste oxigenul necesar arderii complete, astfel gazele de ardere au un continut minim de particule, umiditate sau compusi organici.

- SIGURANTA: Evacuarea gazelor de ardere nu este influentata de conditiile atmosferice.

Controlul arderii prin tiraj fortat

Alimentarea cu peleti se face automat, cu un snec transportor comandat de un senzor capacitiv.

AVANTAJ: Rezervorul de peleti este independent de corpul centralei, in functie de spatiul disponibil, poate fi folosit cel din dotarea standard 600/800 litri sau un alt recipient de capacitate mare.

SIGURANTA: Sistemul de alimentare cu peleti este prevazut cu elemente de siguranta ce previn avarierea in cazul in care, accidental, sunt antrenate corpuri straine.

Sistem de alimentare automat

Alimentarea cu peleti se face automat, cu un snec transportor comandat de un senzor capacitiv.

AVANTAJ: Rezervorul de peleti este independent de corpul centralei, in functie de spatiul disponibil, poate fi folosit cel din dotarea standard 600/800 litri sau un alt recipient de capacitate mare.

SIGURANTA: Sistemul de alimentare cu peleti este prevazut cu elemente de siguranta ce

previn avarierea in cazul in care, accidental, sunt antrenate corpuri straine.

Automatizare

Prin automatizarea completa cu aparatura performanta si soft conceput impreuna cu firma austriaca SIGMATEK GmbH &Co KG, se realizeaza controlul total al producerii energiei termice cat si al tuturor sistemelor ce compun instalatia si face posibila integrarea acestora in sisteme complexe de incalzire.

Display-ul touch color va furnizeaza informatii complete privind functionarea echipamentului.

Echipamentele pot fi supravegheate si programate de la distanta, printr-o conexiune la internet, astfel aveti intotdeauna controlul sistemului Dvs. de producere a energiei termice

Sisteme de siguranta

Set de protectie electrica

Deoarece fluctuatiile/intreruperile de curent electric ce pot afecta componentele electronice ale centralei termice sau pot perturba buna functionare am inclus in dotarea standard un set de protectie:UPS cu functiuni de invertor, stabilizator, redresor si 2 acumulatori.

Traductor de curgere ( fluxostat)

Sesizeaza circulatia agentului termic in intalatie si asigura protectia in cazul pierderii agentului termic, blocarii pompei de circulare sau a circuitului termic.

Alte elemente de siguranta:

– manometru de presiune, manometru de termperatura agent termic

– aerisitor

– supapa de siguranta ( 5bar)

Exemple de aplicatii

Ardem peleti fabricati din partea biodegradabila a tot ceea ce produce azi societatea.

Luptam cu tarie pentru stoparea defrisarilor in scopul fabricarii de peleti premium si ne alaturam campaniilor ce militeaza pentru ca generatiile viitoare sa primeasca o planeta curata si vie.

Industria echipmentelor de producere a energiei termice si electrice cu peleti este limitata la utilizarea peletilor din lemn, iar principala preocupare a producatorilor de peleti este ccesul la cat mai multe teritorii impadurite, pentru a le defrisa si a obtine materie prima pentru asa-zisa energie verde.