Incalzire eficienta a incintelor cu inaltime mare

Prin aplicarea tehnologiei de ardere ecoHORNET la tuburile radiante s-a facut posibila incalzirea eficienta si ecologica a spatiilor inalte precum hale industriale, depozite, sali de sport, biserici, complexe expozitionale, service, garaje, hangare, etc.

Gama de puteri: 35-120 kW

Energie verde si independenta energetica

In premiera mondiala, SC ECOHORNET SRL foloseste arzatoarele cu peleti pentru incalzirea tuburilor radiante.Lipsa particulelor de cenusa si a fumului din gazele arse si temperatura la care se realizeaza arderea fac posibila transmiterea energiei termice rezultate in urma arderii peletilor in tuburile radiante cu mentinerea parametrilor de functionare constanti pe toata durata utilizarii si fara a necesita operatiuni de curatire repetate.

- Spre deosebire de tuburile radiante clasice pe gaze, lichide sau electrice, utilizarea arzatoarelor ecoHORNET cu peleti pentru tuburi radiante ofera acestor mari consumatori posibilitatea obtinerii unei energii termice ieftine, ecologice si eficiente.

Economii financiare prin utilizarea energiilor nepoluante

Incalzirea cu tuburi radiante si peleti este cea mai eficienta si economica varianta pentru spatiile inalte deoarece caldura se transmite obiectelor, persoanelor care se

afla in perimetrul deservit de tuburile radiante, realizandu-se o incalzire directionata pe zonele de lucru, identica cu incalzirea produsa de razele solare, si nu a unui volum de aer imens.

Unul din avantajele incalzirii cu tuburi radiante este ca efectul incalzirii apare la cateva minute dupa pornirea arzatorului, nefiind necesara functionarea sistemului atat timp cat nu se desfasoara activitati in spatiul respectiv. Caldura rezultata se distribuie uniform si confortabil fara curenti de aer si praf.

NOU: 3 in 1

Arzatorul ecoHORNET cu peleti pentru tuburi radiante este un sistem complex, raspunde la toate cerintele acestui gen de utilizatori. De exemplu, arzatorul de 60 kw cu tuburi radiante realizeaza:

incalzire a 400 mp hala industriala prin radiatie

incalzire a 400 mp birouri, show-room cu aer cald

produce 500 – 700 litri apa calda de consum la 65ºC/8 ore.

Consumul de combustibil este extrem de redus si nu depaseste 1,2 euro/h.

Dotare standard

arzator tip injector ecoHORNET

sistem de alimentare cu snec

automatizare Sigmatek GmBH, display touch color, control si comanda prin internet

rezervor de peleti capacitate 300kg

termostat ambiental radio

set de protectie electrica cu UPS, stabilizator, invertor, redresor 2 acumulatori 50A

tub radiant si reflector

Optional: schimbator de caldura din inox alimentar, pentru producere apa calda de consum.

Montajul tuburilor radiante se realizeaza la o inaltime de 4,5-10 m iar suprafata incalzita prin radiatia tuburilor variaza intre 100 si 400 mp.

Arzator

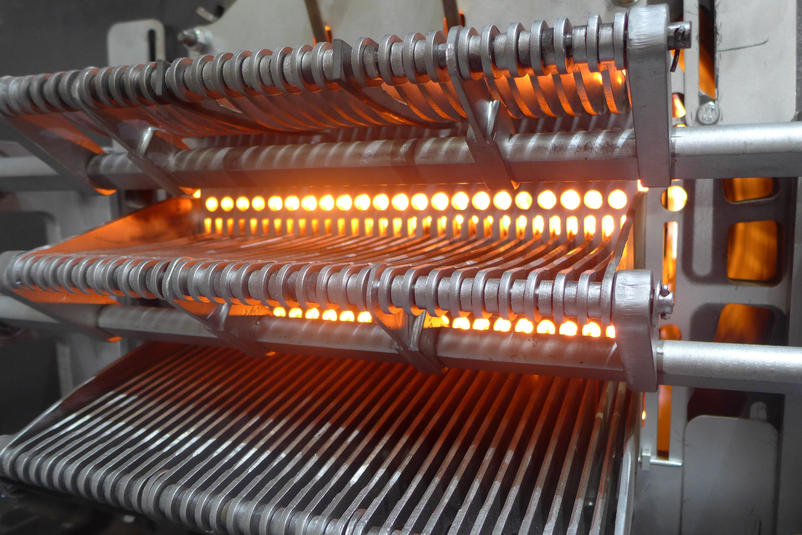

Arzatorului multisistem ecoHORNET patentat dezvolta temperaturi de ardere a peletilor de peste 1250°C, toata puterea calorica a combustibilului este valorificata, transformandu-se in energie termica. Randamentul arderii este aproape de 100%, arderea este completa, fara fum in gazele de ardere.

Arzatorul ecoHORNET este mobil, cu autocuratire si accelerarea arderii pentru cazul utilizarii unor peleti mai slabi energetic.

Arzatorul si camera de ardere sunt fabricate din inox special, rezistent la temperaturi peste 1300°C si la variatii de temperatura.

Sistem de accelerarea a arderii si curatare gratar

Echipamentele au in dotare mecanisme de accelerare a arderii, pentru a pastra constanta puterea nominala, chiar daca se utilizeaza peleti cu putere calorica mai mica.

-

Tub radiant in forma de U sau liniar:

-

ATR20 – tub radiant U 2 x 4-7m

-

ATR40 – tub radiant U 2 x 8-11m

-

ATR60 – tub radiant U 2 x 12-15m

-

Ecran reflectorizant din aluminiu cu rolul de a uniformiza si directiona radiatia;

Controlul arderii prin tiraj fortat

Arderea fara fum si gudron in gazele evacuate permite functionarea cu tiraj fortat. Exhaustorul este montat la evacuarea de gaze de ardere.

Functionarea cu tiraj fortat asigura 100% controlul fluxului de oxigen necesar arderii, arderea este uniforma in toata masa de peleti aflati in arzator se realizeaza arderea completa, inclusiv a particulelor de fum.

Fiecare particula de pelete primeste oxigenul necesar arderii complete, astfel gazele de ardere au un continut minim de particule, umiditate sau compusi organici.

-

SIGURANTA: Evacuarea gazelor de ardere nu este influentata de conditiile atmosferice.

Sistem de alimentare automat

Alimentarea cu peleti se face automat, cu un snec transportor comandat de un senzor capacitiv.

AVANTAJ: Rezervorul de peleti este independent de corpul centralei, in functie de spatiul disponibil, poate fi folosit cel din dotarea standard 600/800 litri sau un alt recipient de capacitate mare.

SIGURANTA: Sistemul de alimentare cu peleti este prevazut cu elemente de siguranta ce previn avarierea in cazul in care, accidental, sunt antrenate corpuri straine.

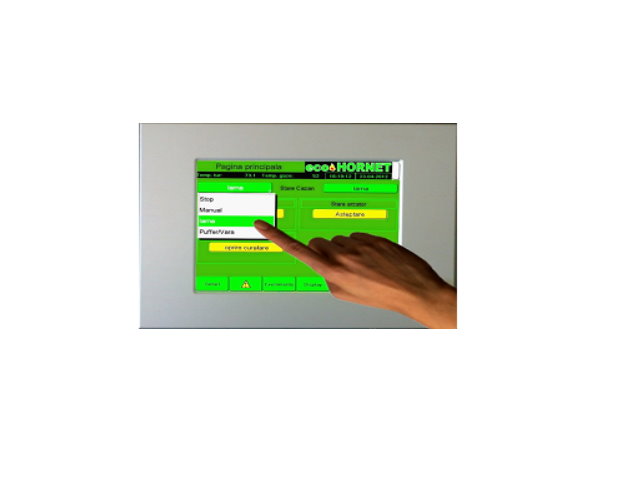

Automatizare

Prin automatizarea completa cu aparatura performanta si soft conceput impreuna cu firma austriaca SIGMATEK GmbH &Co KG, se realizeaza controlul total al producerii energiei termice cat si al tuturor sistemelor ce compun instalatia si face posibila integrarea acestora in sisteme complexe de incalzire.

Display-ul touch color va furnizeaza informatii complete privind functionarea echipamentului.

Echipamentele pot fi supravegheate si programate de la distanta, printr-o conexiune la internet, astfel aveti intotdeauna controlul sistemului Dvs. de producere a energiei termice

Sisteme de siguranta

Set de protectie electrica

Deoarece fluctuatiile/intreruperile de curent electric ce pot afecta componentele electronice ale centralei termice sau pot perturba buna functionare am inclus in dotarea standard un set de protectie:UPS cu functiuni de invertor, stabilizator, redresor si 2 acumulatori.

Termostat ambiental radio

Permite programarea temperaturii ambientale, orele de incalzire intr-un program zilnic si saptamanal.

Comanda pornirea si oprirea arzatorului in functie de temperatura si orarul de functionare setate.

Combustibil utilizat: Peleti cu continut de minim 80% masa lemnoasa, diametru 6-12mm, lungime 5-35mm, umiditate <10%, densitate 650-750 kg/m³

Aplicatii:

Incalzire incinte cu inaltime mare

-hale industriale

– depozite

– sali de sport

– ateliere service, garaje

– hangare

– complexe expozitionale

Locatie: Bucuresti

Echipament: arzator ecoHORNET AHP 60 mobil cu tuburi radiante in U, 12 ml

-

Aceasta companie produce celule din beton pentru transformatoare electrice. Pe timpul iernii circa 3 luni, compania oprea activitatea si concedia muncitorii deoarece era imposibil de incalzit hala de productie h=15m la temperatura de uscare a betonului.

-

Astfel, in 8 ore se executa 4 turnari a 200 mp, circa 800 mp placile de beton, cu un cost de doar 10 euro